TECHNOLOGY

AND - FEATURES

At KRUG EXPEDITION, every detail is built for performance, comfort, and durability—from reinforced modules to smart interiors and advanced materials.

( MODULE BODY )

Robust

Module Body

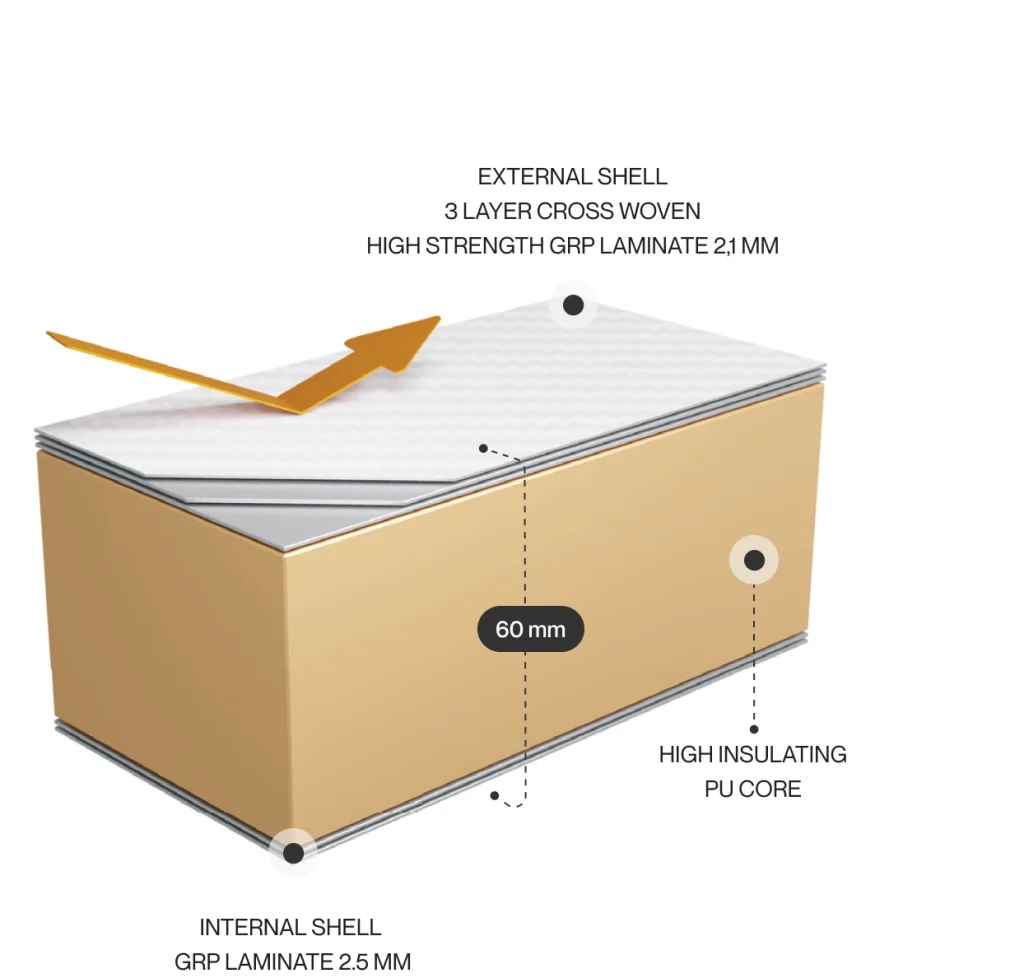

All our modules are manufactured in-house, which enables us to ensure quality control at every stage of production—from raw materials to the finished product. We build our modules using reinforced sandwich panels that offer exceptional insulation and performance.

( LAMINATE )

Our custom outer laminate is made of high-density, cross-woven fiberglass layers impregnated with epoxy resin.

This combination delivers greater strength and impact resistance than standard laminates, which often use brittle polyester resin with weak fiberglass bonding. Our laminate contains 70% fiberglass vs. 25–50% in typical GRP panels. Combined with epoxy resin, it provides excellent tensile strength, stiffness, durability.

It allows us to use a 2 mm thick laminate while still outperforming 3–4 mm conventional laminates, and it eliminates common issues like surface cracking. Compared to aluminum, our laminate is lighter, has three times the tensile strength, and is less heat conductive and more resistant to weather-related wear.

( MODULE Features )

( HEATING SYSTEM )

Efficient, reliable heating

with diesel for maximum comfort

For all KRUG EXPEDITION cabins, we install the Scheer Nano diesel-powered liquid heater as standard, providing a dependable and efficient heating solution tailored for expedition needs. This system offers quiet operation and stepless power control, maintaining a consistent interior temperature for optimal comfort.

Diesel heating ensures maximum independence by drawing fuel directly from the vehicle’s main tank, effectively eliminating the need for separate gas supplies. Unlike gas systems that consume over 80% of your gas in winter and often require extra bottles and adapters, diesel heating is simpler and more reliable.

( WATER SUPPLY )

Our water supply system

is designed for maximum reliability.

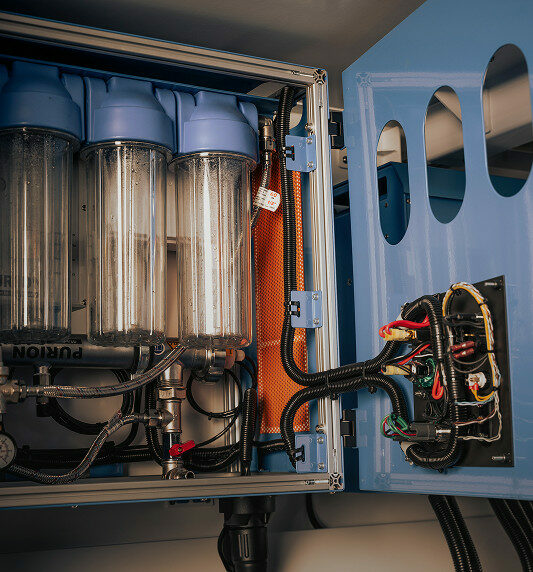

Each Krug module is equipped with a backup water pump that can be easily switched over to in case the main pump fails, saving the effort of changing or repairing the main pump while travelling. We optionally install a water filling station to filter and treat the water when filling the fresh water tanks.

The water is pre-filtered via a filtration system with 3 pre-filtering stages with activated carbon and a filtration capacity of up to one micron (10 nanometers). Water is then treated with the PURION 1000 UV unit. The UV lamp emits a wavelength of 254 nm without producing any ozone.

( POWER SUPPLY )

Our modules and their equipment are designed to provide a complete all-electric experience.

Powerful solar panels, a generously sized battery bank and matching components by Victron (an established manufacturer of energy systems for marine and off-grid applications) ensure a reliable supply of energy wherever you may be, so that you don’t have to worry about procuring gas bottles and / or adapters.

Our standardized energy supply system is extremely compact and includes a battery bank with a capacity of 600 Ah at 25.2 volts (24 kW/h). To achieve these impressive values, we rely on the latest lithium-ion technology, known for its high energy density (high energy content with low weight and volume).